A Guide to Powder Coating in UAE for Villa Projects

A Guide to Powder Coating in UAE for Villa Projects

Ever noticed how quickly paint fades, peels, or chalks on villas across the UAE? It’s a constant battle against the elements. For homeowners, architects, and developers, the climate is a relentless challenge. This is where powder coating comes in—it’s much more than just a lick of paint. Think of it as a tough, baked-on shield for your investment, delivering serious durability against the region’s intense sun, dust, and humidity.

Why Powder Coating Is a Smart Investment in the UAE

When building or renovating in the UAE, every material choice must be made with the demanding environment in mind. Intense sun, high humidity, corrosive coastal air, and frequent sandstorms will quickly destroy conventional liquid paints.

Powder coating offers a powerful solution. Unlike liquid paint that needs solvents to dry, powder coating is a dry powder electrostatically applied to a metal surface, like an aluminium window frame. The frame then goes into an oven, where the powder melts and fuses into a tough, single, uniform layer.

Protection Against the Elements

This thermal bonding process creates a finish that is miles tougher than traditional paint. For a villa in a community like Arabian Ranches, this means window frames can stand up to windblown sand without chipping or scratching.

For a waterfront property on Palm Jumeirah, it provides incredible resistance to the corrosive salt spray that chews through other finishes. This resilience is why it’s the go-to choice for high-performance systems like Cortizo's Cor Vision Plus sliding doors or Vetro Slide systems, ensuring they look great and perform flawlessly for years.

A Lasting Aesthetic Choice

The benefits go far beyond just protection. The process ensures a completely consistent colour and texture, free from the drips, runs, and brush marks that can ruin a liquid paint job. This flawless finish is exactly what architects and designers in Dubai and Abu Dhabi demand for high-end residential projects.

Because the finish is literally baked onto the metal, powder-coated surfaces are far less likely to fade under the harsh UAE sun. This means the deep black or contemporary grey frames on your villa will hold their colour for much longer, preserving your property's value and kerb appeal with minimal fuss.

This combination of versatility and resilience is a key reason why understanding the benefits of aluminium for modern homes in the UAE is so crucial. Powder coating takes the natural strengths of aluminium and elevates them, creating a product perfectly suited for the region.

How the Powder Coating Process Actually Works

To really get why powder coating in UAE is so effective, you need to understand the meticulous process behind it. This isn't just spraying on a bit of colour; it’s a multi-stage technical method designed for maximum adhesion, durability, and a flawless look. The entire journey transforms a dry powder into a resilient, protective skin fused directly onto the metal.

Think of it as a high-tech baking process for metal. Every single step is precisely controlled to ensure the final product—whether it's a Cortizo Cor 70 window frame or a Vetromax façade—can stand up to Dubai’s demanding climate. From the initial prep to the final cure, quality is engineered in at every stage.

Stage 1: Meticulous Surface Preparation

Before any powder even comes near the metal, the surface has to be perfectly clean. This is, without a doubt, the most critical step. The quality of the final finish depends entirely on how well the powder can grip the substrate. Any oil, dirt, or even microscopic dust can create imperfections and weak spots down the line.

The prep work usually involves a few key steps:

- Cleaning and Degreasing: First, the profiles are thoroughly washed to strip away any oils, grease, or contaminants left over from manufacturing.

- Etching or Blasting: For aluminium, a light acid etch or mechanical abrasion is often used. This creates a microscopic texture on the otherwise smooth metal, giving the powder something to really hang on to.

- Pre-treatment: Finally, a chemical pre-treatment like a chromate or non-chromate conversion coating is applied. This not only boosts corrosion resistance but also dramatically improves the bond between the metal and the powder coat.

This foundational work is what ensures that when a villa in Arabian Ranches gets hit by a sandstorm, the finish on its Deceuninck uPVC windows won't chip or peel away.

Stage 2: The Electrostatic Application

Once prepared, the metal profile is moved into a specialised application booth. This is where the magic of electrostatics happens. A high-tech spray gun gives the fine powder particles a positive electrostatic charge as they are sprayed out.

At the same time, the aluminium frame or component being coated is grounded (given a negative or neutral charge). You know how a balloon sticks to a wall after you rub it on your hair? It’s the same principle. The positively charged powder particles are instantly and uniformly attracted to the grounded metal surface.

This electrostatic attraction is incredibly efficient. It ensures the powder wraps around corners and coats complex shapes perfectly evenly, reaching into every nook and cranny of an intricate window profile without any drips or runs—a level of precision that’s simply impossible with liquid paint.

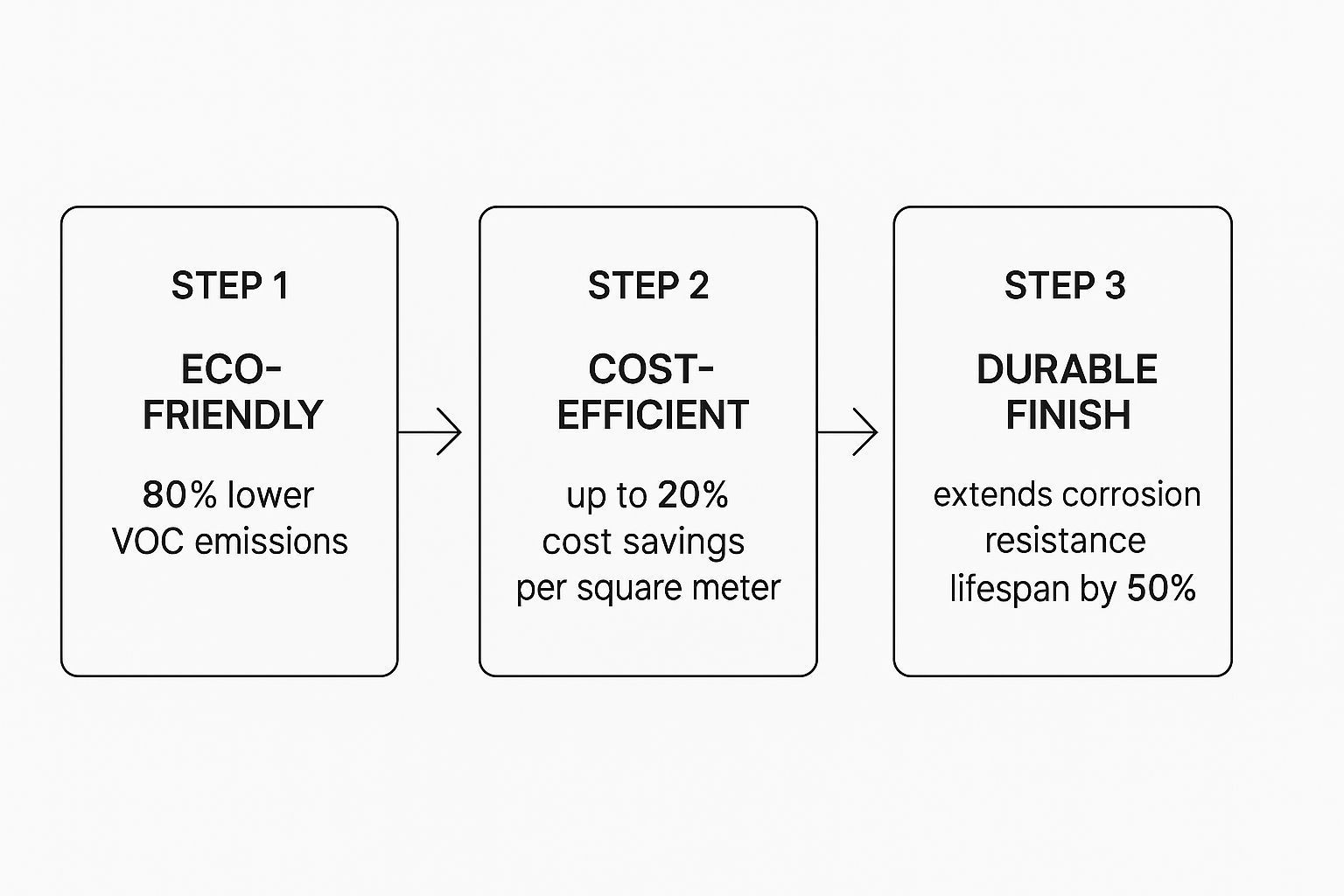

The infographic below really brings home how this efficient process leads to a more sustainable, cost-effective, and durable result.

It clearly shows the path from environmental benefits and cost savings right through to superior longevity, making it an obvious choice for UAE construction.

Stage 3: Curing and Final Quality Checks

With a fine layer of powder clinging to it, the component moves into a large curing oven. Here, it’s heated to temperatures between 160°C and 210°C. The heat melts the powder, allowing the individual particles to flow together and form a smooth, liquid-like film over the surface.

As the heating continues, a chemical reaction called cross-linking takes place. This reaction bonds the polymer resins in the powder together, creating a hard, dense, and incredibly durable network. It's this "baking" that gives powder coating its famous toughness and resistance to scratches, chemicals, and UV damage.

Of course, working with high-temperature ovens requires strict fire safety protocols. This makes knowing how to operate a fire extinguisher an absolutely essential skill for everyone working in a powder coating facility.

After cooling, the finished product goes through a series of tough quality checks. Technicians inspect for colour consistency, gloss level, coating thickness, and adhesion to make sure it meets strict standards before it's approved for installation in a high-end villa or a new commercial development.

Benefits of Powder Coating in the UAE Climate

Let's be honest: the UAE environment is the ultimate stress test for any building finish. The combination of scorching sun, coastal humidity, and abrasive sandstorms can destroy standard paints in just a few years. This is precisely where powder coating proves its value, offering a tough, factory-baked shield that traditional liquid paint simply can't match.

These aren't just technical advantages; they translate into real, long-term value for anyone building or renovating here. Whether it’s for a sleek Vetromax façade in Downtown Dubai or elegant Cortizo windows in a Jumeirah villa, the right finish is what stands between lasting beauty and costly, premature failure.

Unmatched UV and Heat Resistance

The sun in this region is relentless. Its powerful UV radiation bleaches colours and breaks down the chemical bonds in conventional paint, leaving behind a chalky, faded mess. Polyester-based powder coatings, however, are specifically formulated with UV-stable resins that laugh off this constant solar assault.

This means the bold, contemporary dark grey on your Cortizo Cor Vision Plus sliding doors will stay deep and rich, not fade into a washed-out shadow of its former self. Because the finish is baked on, it also reflects more solar radiation, which helps keep the aluminium profiles themselves a bit cooler and reduces how much heat gets transferred into your home.

Superior Corrosion and Humidity Defence

For any property near the coast—from Palm Jumeirah to Saadiyat Island in Abu Dhabi—the salty sea air is a constant corrosive threat. This saline humidity attacks standard painted aluminium, causing it to pit, blister, and ultimately fail.

Powder coating creates a seamless, non-porous barrier that completely seals the metal off from moisture and salt. It’s not just a top layer; the process starts with a multi-stage chemical pre-treatment that prepares the aluminium to resist corrosion before a single grain of powder is applied.

This protective shield is critical for keeping systems like bi-fold doors and windows operating smoothly. It prevents the corrosive build-up that causes frames to stick, jam, or degrade, ensuring your investment stays functional and beautiful for years.

The demand for durable solutions like this is booming. The UAE's paints and coatings market, where powder coatings are a key segment, was valued at USD 1.06 billion in 2024 and is projected to hit USD 1.66 billion by 2033. This growth is fuelled by major construction projects that demand high-performance, climate-resilient finishes. Explore more on the UAE's coatings market trends.

Resilience Against Sand and Dust Abrasion

Sandstorms are a fact of life here, and those fine, wind-driven particles act like sandpaper on building exteriors. This constant abrasion can quickly wear down, scratch, and dull liquid paint, exposing the raw metal underneath to the elements.

Powder coating’s exceptional hardness and chip resistance provide a powerful defence. Because the finish is thermally fused to the metal, it’s far tougher and more flexible than a brittle film of paint.

- Impact Resistance: It can easily withstand the minor impacts of windblown debris without chipping or cracking.

- Scratch Resistance: The hard surface resists the fine scratches that accumulate during sandstorms, keeping the finish looking pristine.

- Easy Maintenance: The smooth surface makes cleaning off accumulated dust simple—often, all it takes is a quick rinse with water.

This durability ensures that window and door systems, even in exposed communities like Arabian Ranches, maintain their clean, sharp appearance with very little upkeep.

Powder Coating vs Traditional Paint in the UAE Climate

| Number | Powder Coating | Traditional Liquid Paint |

|---|---|---|

| UV Resistance | Excellent. Retains colour and gloss for years. | Poor to fair. Fades and becomes chalky quickly. |

| Heat Resistance | Very high. Finish remains stable and intact. | Can soften, blister, or peel in extreme heat. |

| Humidity/Salt Defence | Excellent. Creates a non-porous barrier against moisture. | Prone to blistering and peeling; allows moisture underneath. |

| Sand Abrasion | High. Hard, flexible finish resists scratches and chipping. | Low. Easily scratched and eroded by windblown sand. |

| Durability | Long-lasting (15-20+ years). Fused to the metal. | Shorter lifespan (3-7 years). Sits on top of the surface. |

| Maintenance | Minimal. Easy to clean with soap and water. | Requires frequent repainting and touch-ups. |

As the table shows, while traditional paint might offer a quick, low-cost solution upfront, it simply isn't built for the long haul in this environment. Powder coating is a true investment in longevity.

This resilience is a key reason developers and architects specify powder coating in UAE for premium residential projects where low maintenance and lasting quality are non-negotiable.

Choosing the Right Powder Coat Finish for Your Villa

Picking the right finish for your villa’s window and door frames is about so much more than just the colour. The texture and sheen you choose play a massive role in the final look and the day-to-day performance of your aluminium systems. This one decision directly impacts glare, how much maintenance you'll be doing, and the architectural statement your property makes.

For homeowners and designers here in the UAE, this choice is particularly critical. A finish that looks incredible in a catalogue can behave very differently under the intense desert sun. Get it right, and you’ll enhance comfort and cut down on upkeep—a crucial detail for projects from modern villas in Dubai Hills to waterfront homes on Palm Jumeirah.

Understanding Your Finish Options

When you specify a powder coat, you’ll generally come across four main types of finishes. Each one offers a distinct aesthetic and comes with its own set of practical advantages, making them suited for different applications and architectural styles across the UAE.

- Gloss Finish: This is your shiny, reflective surface that makes colours really pop. It's incredibly smooth and a breeze to clean, but it has a downside: it can highlight even the tiniest surface imperfections and create serious glare in direct sunlight.

- Satin Finish: A hugely popular middle-ground, satin offers a subtle, low-sheen lustre that’s far less reflective than gloss. It delivers a sophisticated look while being more forgiving of minor dust and imperfections, making it a fantastic all-rounder.

- Matte Finish: With almost no reflection, a matte finish provides a modern, understated, and elegant appearance. It excels at diffusing harsh sunlight—a major plus for large glass installations like Cortizo’s Cor Vision Plus systems, as it helps to reduce eye-straining glare.

- Textured Finish: This finish has a slightly rough or sandy feel, designed to add a bit of tactile depth. Its biggest advantage is its uncanny ability to hide fingerprints, minor scratches, and dust, making it a brilliant low-maintenance option for high-traffic areas.

Practical Applications in UAE Villas

The real trick is to match the finish to the specific challenge you're facing. For example, a dark, glossy frame on a south-facing window in Arabian Ranches would probably create way too much reflection. A matte finish, on the other hand, would absorb that light beautifully and create a much softer look.

Or think about a large bi-folding door system opening onto a pool deck. A textured powder coat would not only add a unique design element but would also be more resilient against the minor scuffs and scrapes that are inevitable in family-centric outdoor living spaces. This durability is exactly why it’s such a smart choice for active homes.

For projects aiming for that sleek, contemporary aesthetic, a satin or matte black finish on slim aluminium profiles like the Cortizo Cor 70 is a winning combination. It delivers a sharp, minimalist look that complements modern UAE architecture without the harsh reflections of a full gloss.

Navigating Colours with the RAL System

Beyond the texture, your colour choice is obviously paramount. The industry standard for specifying colours in powder coating is the RAL colour system, a European colour-matching standard that ensures total consistency across different manufacturers and projects. The system offers a massive palette of hundreds of precise hues.

This standardisation is vital for architects and developers. It guarantees that the window frames installed on a villa will perfectly match the balustrades or other architectural elements, even if they're coated at different times or by different companies.

When selecting a colour, it's also smart to consider community design guidelines, especially in master-planned communities across Dubai and Abu Dhabi. Choosing a RAL colour that aligns with the approved palettes ensures your project moves forward without any frustrating delays. For more on this, our guide on choosing the right glass and aluminium for your UAE villa offers some valuable context.

Powder Coating and Green Building Regulations in the UAE

In the UAE, building sustainably isn't just a trend—it's a regulatory requirement. For architects, developers, and homeowners alike, hitting the targets set by frameworks like Abu Dhabi's Estidama or the Dubai Green Building Regulations is non-negotiable. This is where powder coating for aluminium and uPVC systems really shines, offering a clear path to compliance and responsible construction.

It all starts with what isn't in the mix: Volatile Organic Compounds (VOCs). Unlike traditional liquid paints that release harmful solvents into the air as they cure, powder coating is a solid, inert finish. This means virtually zero emissions, contributing directly to better indoor and outdoor air quality—a critical factor in green building assessments.

This eco-conscious advantage is a major reason why the global powder coatings market, valued at USD 16.54 billion in 2024, is expected to climb to USD 27.25 billion by 2034. It’s simply a better, cleaner, and more durable technology perfectly suited to the demands of modern architecture in the UAE.

Reducing Waste Through Process Efficiency

The environmental benefits go far beyond air quality. The powder coating process itself is incredibly efficient. Any powder that doesn't adhere to the metal during the initial spray—known as overspray—isn't just thrown away. Instead, it’s captured by advanced reclamation systems, filtered, and reused in future applications.

This creates a closed-loop system that dramatically cuts down on material waste, often achieving a transfer efficiency of over 95%. For a large-scale villa project in a community like Dubai Hills, this smart resource management significantly reduces the development's environmental footprint, ticking a major box for sustainability ratings.

When you specify powder-coated systems from brands like Cortizo or Deceuninck, you’re not just choosing a finish. You’re opting for a manufacturing process designed to minimise its environmental impact from the very beginning. It's a smart decision for any project aiming for a high Estidama Pearl or Al Sa'fat rating.

Durability as a Form of Sustainability

Perhaps the most significant green credential of powder coating is its sheer longevity. A properly applied powder coat is engineered to last for decades, standing strong against the UAE's intense sun, humidity, and sand without chipping, fading, or corroding.

This incredible durability is sustainability in action. A longer lifespan means less need for replacements and refinishing down the line, which translates to less energy consumed and less waste generated over the building’s entire life. Every time a window frame has to be repainted or replaced, it comes at an environmental cost.

By investing in a durable powder-coated finish from day one, you’re making a long-term commitment to lower maintenance and a smaller carbon footprint. For those looking to understand these impacts in greater detail, the principles of carbon accounting in construction and real estate offer a deeper look into how these choices contribute to a project's overall green credentials.

Maintaining Your Powder Coated Surfaces

Even though the factory-baked finish of **powder coating in UAE** is incredibly tough, a bit of simple care goes a long way. This is especially true with the constant presence of dust and sand, but the good news is that keeping it looking pristine is surprisingly easy. No harsh chemicals or aggressive scrubbing needed.

The hard, non-porous surface created during the curing process makes it difficult for dirt to get a real grip. It means that for most properties, from villas in Arabian Ranches to high-rise apartments in Dubai Marina, a gentle wash is all it takes to restore that fresh-from-the-factory look.

Simple Cleaning for Lasting Results

For general upkeep, a bucket of clean water mixed with a mild, non-abrasive detergent is your best tool. Just use a soft cloth or sponge to gently wipe down the frames of your Cortizo or Deceuninck windows and doors, lifting away any accumulated dust.

After washing, it’s vital to rinse the surfaces thoroughly with fresh water. If you let soap residue dry on the finish, it can leave a film that actually attracts more dust over time. A quick clean every few months is enough to keep your finish looking brand new.

Expert Tip: Never, ever use abrasive cleaners, scouring pads, or harsh chemical solvents like acetone or thinners on powder-coated surfaces. They can permanently damage the finish, dulling its appearance and stripping away its protective qualities.

Post-Sandstorm Inspection Checklist

The UAE’s occasional sandstorms can leave a thick layer of fine, abrasive dust on your property. Once the skies clear, a quick inspection and clean-up will prevent any long-term issues.

Just follow this simple checklist:

- Rinse First, Wipe Second: Always start by gently hosing down the surfaces with clean water. This lifts off the larger sand particles without scratching the finish, which is a real risk if you start wiping a dry, dusty frame.

- Wash Gently: Now, use your mild soap solution and a soft cloth to clean the frames. Pay extra attention to corners and tracks where dust loves to hide.

- Inspect Seals and Tracks: While you’re cleaning, check that the tracks of your Vetro Slide or Cor Vision Plus doors are clear of debris. Sand build-up can stop them from sliding smoothly and even damage the mechanism.

- Final Rinse: Finish with a thorough rinse of clean water to wash away every last bit of dust and soap, leaving a spotless surface.

This proactive approach doesn't just maintain the look of your window and door systems; it ensures their mechanical parts keep working flawlessly. For a more detailed breakdown, you can explore these 5 maintenance tips for aluminium windows and doors in the UAE climate.

Common Questions About Powder Coating

When you're finalising the finishes for a villa or commercial project here in the UAE, a few practical questions always come up. To help, we’ve put together answers to the queries we hear most often from architects, homeowners, and developers.

It’s all about helping you make a confident choice, especially when specifying for high-end window and door systems from brands like Cortizo, Deceuninck, or Vetromax.

How Long Does Powder Coating Last in the UAE?

This is one of the biggest draws of powder coating – its incredible lifespan. A high-quality, professionally applied powder coat on an aluminium window or door frame will easily last 15 to 20 years, sometimes even longer, without any major fading, chipping, or peeling.

The finish is essentially baked on, creating a fused layer that’s built to handle the region’s intense UV radiation, high humidity, and the occasional sandstorm. It’s a far tougher solution than a standard lick of liquid paint.

Can I Get a Custom Colour for My Project?

Absolutely. Powder coating opens up a huge world of colour possibilities, usually specified using the RAL colour system.

Using a standardised palette like RAL is crucial because it guarantees every single component—from the window frames to the façade panels—is a perfect, consistent match. Whether you need to meet the specific guidelines of a community like Arabian Ranches or want a unique hue for your design, a custom RAL colour can be sourced for you.

Is Powder Coating Scratch-Resistant?

Yes, it’s highly scratch-resistant. During the curing process, the powder melts and forms a hard, cross-linked polymer finish that is much tougher than a simple layer of paint.

This makes it perfect for high-traffic spots or surfaces that get a lot of wear and tear, like the sliding doors leading to a patio or the windows on the ground floor. While it's not completely indestructible against a heavy, deliberate impact, it easily shrugs off the minor scuffs and scrapes of daily life and even the abrasive effect of windblown sand.

It's this inherent toughness that gets it specified for demanding jobs. The finish stays looking pristine for years, protecting the property's look and value with almost no effort.

This demand for durability is clear right across the UAE's protective coatings market, where there's a strong shift towards advanced tech that focuses on corrosion resistance. You'll see a mix of chemistries like polyester and polyurethane used everywhere from civil engineering to industrial sites to combat the region's harsh conditions. You can learn more about the UAE's protective coatings market here.

Can Powder Coating Be Repaired If It Gets Damaged?

Even though powder coating is incredibly durable, a deep gouge or a serious scratch can happen.

For minor scuffs, you can often just buff them out. For more significant damage, you can perform localised repairs. Specialised kits with colour-matched liquid paints or fillers are available to touch up the affected spot. If the damage is really extensive, the best approach is to have the component professionally stripped and recoated to get that flawless finish back and restore its full protective strength.

If you're planning a renovation or villa upgrade in the UAE, Swift Rooms can help you specify the best window and door system for your project. Contact us today for a quote or consultation.